Parylene Engineering

Parylene Coating and Consultation for Aerospace, Automotive, Medical, Electronic and Engineering Applications.

Parylene Conformal Coating for Your Industry

30 Years of Parylene Coating Solutions

We provide Parylene Vapor Deposited Conformal Coating services. Parylene Vapor Deposited Conformal Coating is a polymer deposited in vacuum as gaseous nano molecules polymerize to form a thin film of protective parylene barrier. Thickness can be as thin as a micron. This film is inert thus it resists very aggressive chemicals. The film also has desirable electrical properties like a very high dielectric strength. The mechanical properties are also excellent providing a very low coefficient of friction. Parylene Vapor Deposited Conformal Coating is considered by many to be the ultimate conformal coating for the protection of devices, components and surfaces in the electronics, instrumentation, aerospace, medical and engineering industries. Parylene provides exceptional protection for the most extreme environmental conditions.

Parylene Coating Process and Benefits

Parylene C

The most widely used dimer, providing a useful combination of properties, plus a very low permeability to moisture, chemicals, and other corrosive gases.

Parylene N

Provides high dielectric strength and a dielectric constant that does not vary with changes in frequency. Best selection where greater coating protection is required.

Parylene D

Maintains its physical strength and electrical properties at higher temperatures.

Parylene Coating Case Studies

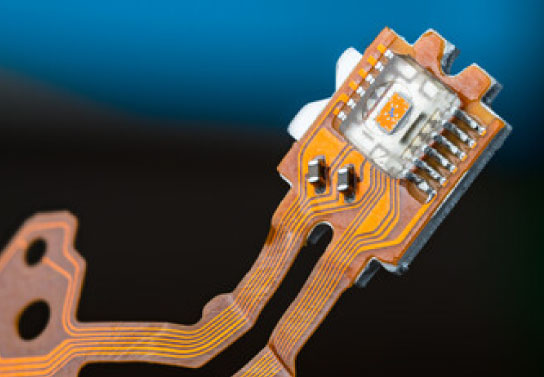

Thermal Sensor on a Flexible Parylene Substrate

A Three Dimensional Multi-Walled Carbon Nanotube based Thermal Sensor on a Flexible Parylene Substrate

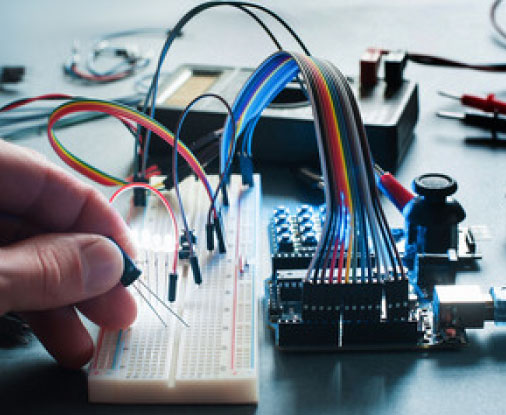

Parylene Coating to Waterproof Electronics

The goal is to implement waterproofing techniques with minimum cost, while maintaining durability, aesthetics, and normal cell phone capabilities.

Parylene-based Multielectrode for Neural Stimulation and Recording

Flexible electronics are gaining popularity in applications where mechanical flexibility, large area, low cost and ease of fabrication are required.

Frequently Asked Questions

Parylene N is the un-substituted polymer obtained by polymerization of the para-xylylene intermediate. Chlorinated parylenesEdit. Repeating unit of parylene C.

Parylene conformal coating is a thin film coating technology used to improve the capabilities of leading-edge technologies. Applied as vapor, the coating layer perfectly conforms to complex shapes and provides complete and even coverage.

Coatings of parylene are often applied to electronic circuits and other equipment as electrical insulation, moisture barriers, or protection against corrosion and chemical attack. They are also used to reduce friction, and in medicine to prevent adverse reactions to implanted devices.

![DQS-MED_ISO9001-2015_blue_A3-[Converted] DQS-MED_ISO9001-2015_blue_A3-[Converted]](https://paryleneengineering.com/wp-content/uploads/elementor/thumbs/DQS-MED_ISO9001-2015_blue_A3-Converted-q80axhh9ng6w3tn4cav5qn6ln81imoxnftzvm5g2k8.png)